© All rights reserved

Plastic Machinery

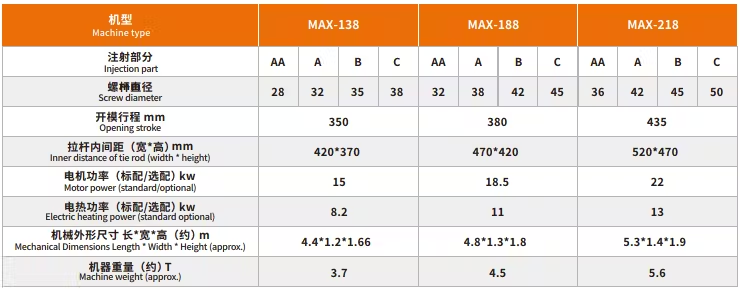

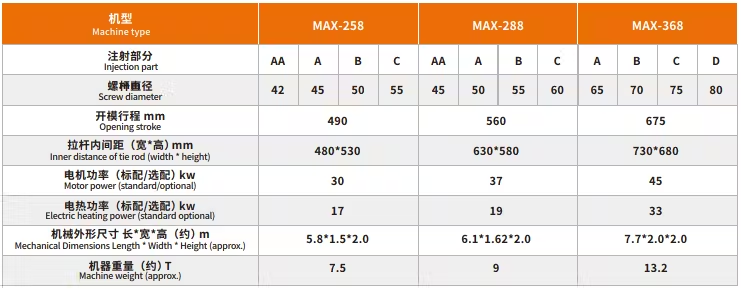

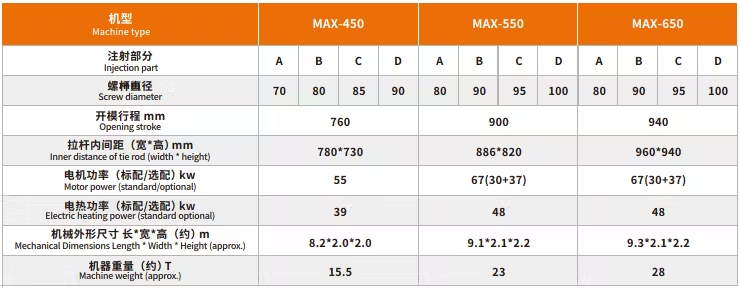

Horizontal Injection Moulding Machine

Details

1. Toggle clamp unit

2. Hydraulic or electric plasticizing units.

3. Utilization of servo drive, servo motor and gear pump for the hydraulic system.

4. Variety of screw and barrel sizes available to choose from.

5. KEBA or Techmation controllers to choose from.

6. Automatic lubrication system.

7. Variety of option and upgrades available.

8. Oil bypass filter.

9. 380V & 220V power outlets.

10. Standard equipment include: adjustable foot pad, hopper magnet, manual book, tool box,

hex key set, small tool set, spare heater bands, spare thermocouples, spare filters,

controller access key, o-rings, fuses, door stoppers, screw tip set, extended nozzle.

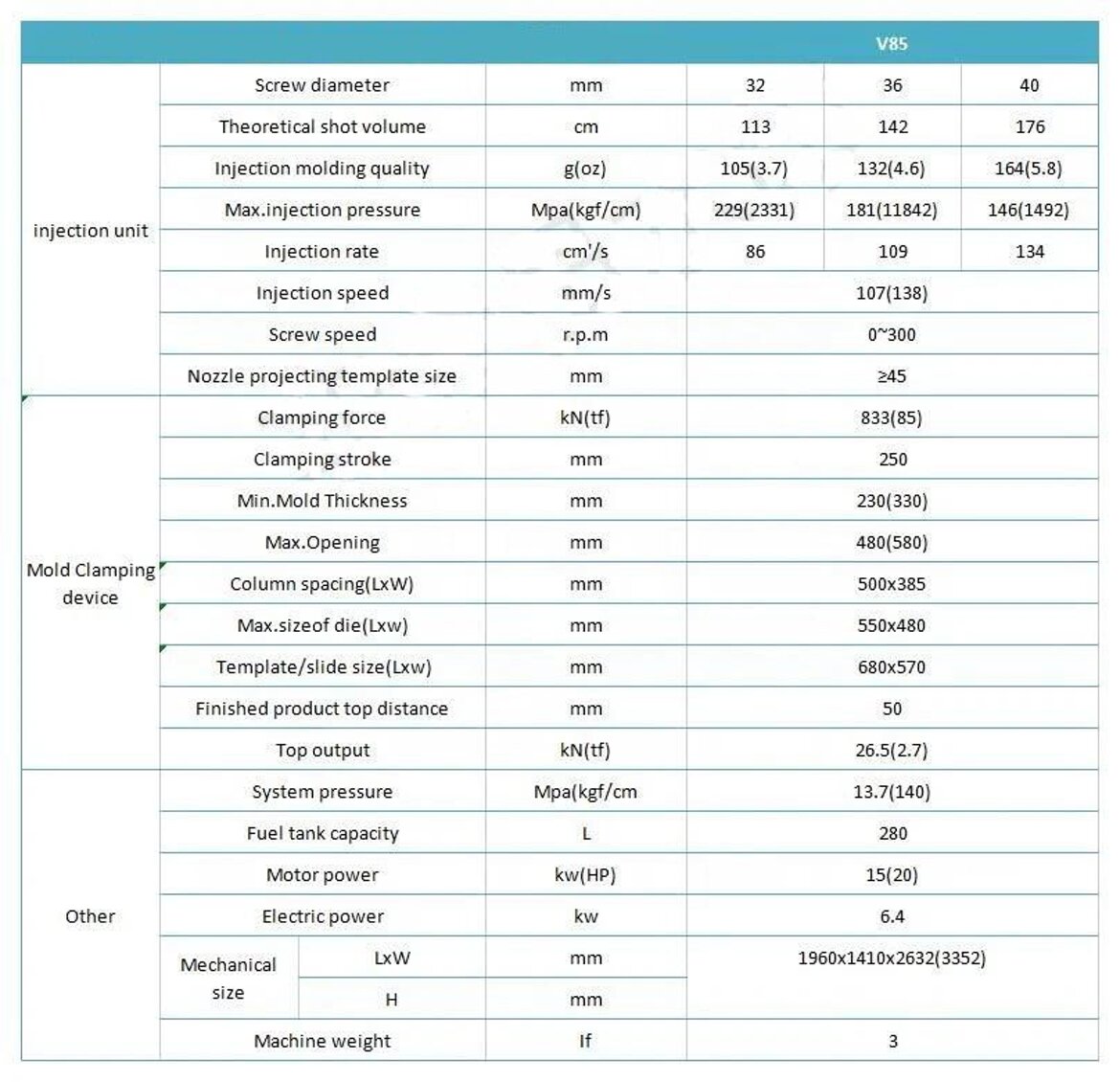

Vertical Injection Moulding Machine

Details

1. Hydraulic clamp unit

2. Hydraulic or electric plasticizing units.

3. Utilization of servo drive, servo motor and gear pump for the hydraulic system.

4. Variety of screw and barrel sizes available to choose from.

5. Mirle controllers.

6. Automatic lubrication system.

7. Variety of option and upgrades available.

8. Oil bypass filter.

9. 380V & 220V power outlets.

10. Standard equipment include: adjustable foot pad, hopper magnet, manual book, tool box,

hex key set, small tool set, spare heater bands, spare thermocouples, spare filters,

controller access key, o-rings, fuses, screw tip set, extended nozzle.

Contact us

sales@plastengco.com

© All rights reserved